GRAVEL

HORIZONTAL HEAVY-DUTY PUMP

The Gravel Series represents a significant leap forward in robust slurry pumping solutions, specifically engineered to tackle the challenges of highly abrasive and corrosive slurries containing large solids.

These pumps excel in efficiently handling abrasive slurries with large particles, delivering consistent performance while minimizing maintenance and ownership costs. Built with a robust, modular design, the Gravel Series offers easy maintenance and flexibility, with wear components available in a variety of highly resistant alloys tailored to specific applications.

With its outstanding operational efficiency and versatility, the Gravel Series is a dependable solution for industries facing abrasive and demanding pumping scenarios. Its focus on reducing the total cost of ownership makes it an invaluable asset for long-term reliability and performance.

KEY BENEFITS OF OUR GRAVEL PUMP

Maximize pump efficiency

Our proprietary adjustable wear ring technology allows for quick, easy, and safe adjustment of suction-side clearance, even while the pump is operating. By maintaining the optimal gap and preventing solids from grinding between the impeller and the suction side, this innovative technology enhances pump efficiency by 5-10% in slurry applications.

The result is reduced power consumption and a significantly lower cost per tonne pumped, delivering both operational and economic benefits.

Extend wear life of wet parts

By minimizing the gap and preventing recirculation within the pump using the adjustable wear ring, while also eliminating the grinding of solids between the impeller and suction side, EUREKA pumps maintain their design performance throughout their entire lifetime—without the need to increase RPM.

Optimize pump performance

EUREKA pump liners are custom-designed for each application to ensure consistent and predictable wear. This precision allows for optimized maintenance scheduling, minimizing downtime and reducing inventory requirements.

GRAVEL ™ DESIGN

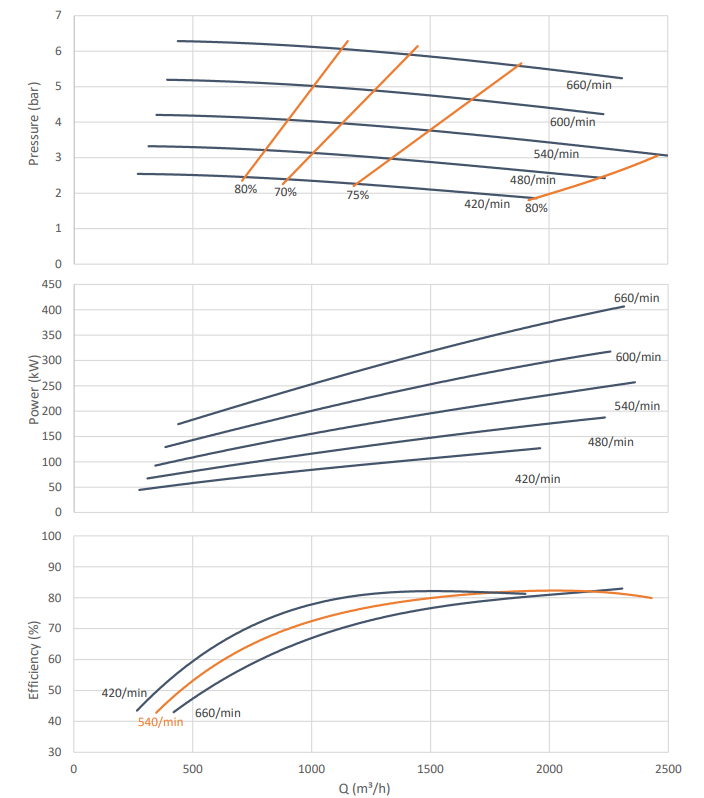

GRAVEL ™ CURVES

GRAVEL ™ APPLICATION

Dredging Industry

- Efficient Dredging: EUREKA® gravel pumps effectively transport water with large particles and high-concentration sediment, facilitating river, port, and waterway dredging.

- Large-flow Transportation: EUREKA® gravel pumps quickly move excavated materials, meeting dredgers’ needs for rapid sediment removal and transfer.

- High Wear Resistance: Made from high-hardness, wear-resistant materials, EUREKA® gravel pumps withstand abrasive materials, extending pump life and reducing maintenance.

- Adjustable Flow and Distance: EUREKA® gravel pumps offer adjustable flow rates and conveying distances, allowing flexible, customized operation.

Shield Tunnel

- Mud Treatment: Extracts and cleans mud containing gravel impurities to maintain site cleanliness.

- Mud Injection: Injects specific materials to enhance mud properties and geological stability.

- Lubrication and Cooling: Delivers lubricant and coolant to shield machine parts for better lubrication and heat dissipation.

- Waste Treatment: Transports waste and residue to designated areas, maintaining a tidy construction site.

Mining Tailings

- Tailings Treatment: Extracts and processes tailings for resource recovery and environmental protection.

- Slurry Transportation: Efficiently transports high-concentration tailings slurry to designated locations.

- Environmental Governance: Reduces the environmental impact of tailings through controlled treatment.

- Silt Pumping: Pumps out silted materials for improved tailings pond treatment efficiency.